Glenbrook Technologies hired NK Labs to develop an automated positioning stage that can be retrofitted onto their X-ray inspection systems as a field upgrade. This stage and software improved the functionality of the X-ray systems by automating the inspection process for higher throughput situations. Applications for this technology include factory inspection of PCB fabrication, SMT and BGA electronics, and medical devices.

NK Labs' own experience in design and production of high density circuit boards gave us valuable insights when designing the automation features and user interface.

Mechanical Development

The sample stage had five degrees of freedom: X, Y, Z, Tilt, and Rotation. The project goal was to drive the motorized stage under computer control to pre-programmed coordinates with 0.005 inch repeatability.

Automated positioning stage with sensors designed by NK Labs

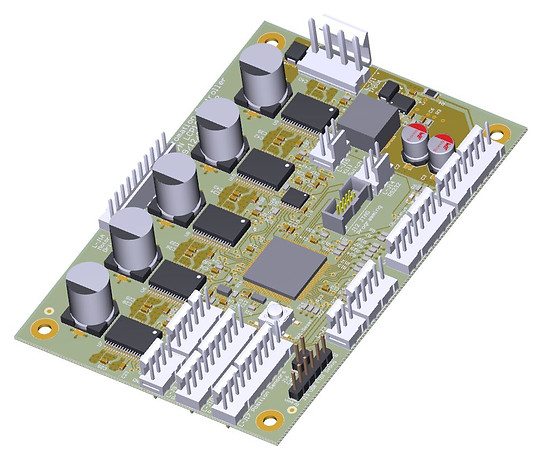

Electrical Development

NK Labs designed the Control Board PCB that uses a microcontroller to interface with the encoders, sensors, and front panel control knobs, to accept commands from the computer over USB, and to drive the motors using H-bridge integrated circuits.

Control Board designed by NK Labs

Firmware Development

Firmware was developed in order to automate the system and to provide additional features. Software limits were added on each of the axes in order to prevent accidental collisions. The host computer relays coordinates to the Control Board, and the firmware will accurately position the motors and ramp the speed up and down to prevent overshoot from the rotational inertia.

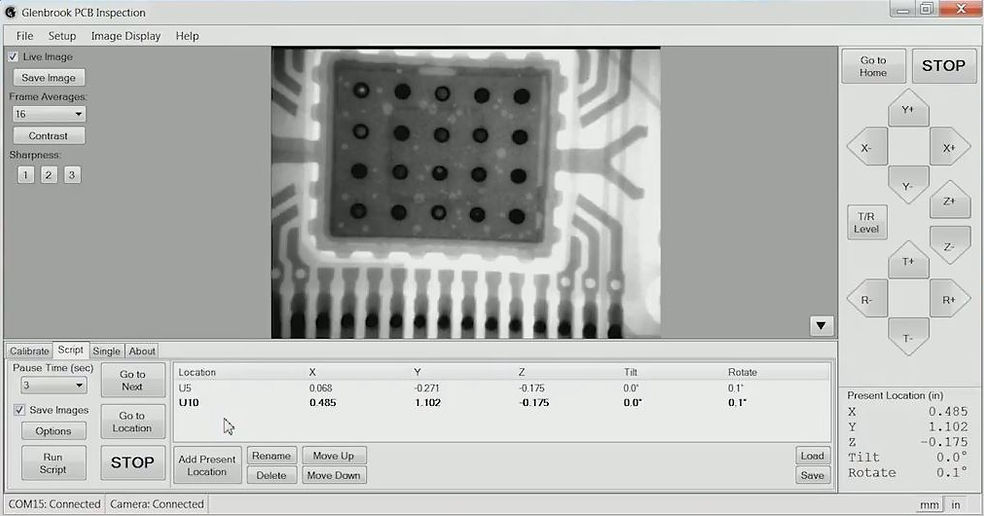

Software Development

In order to control the stage, a Windows application was developed to provide a user interface, display the X-ray images, and communicate with the automation board. Utilizing image processing techniques, the raw X-ray data was enhanced in order to provide crisp images.

X-ray automation control software developed by NK Labs

(courtesy of Glenbrook Technologies)

NK Labs' Seth Newburg and Joe Fenton presenting the final product to Glenbrook Technologies (courtesy of Glenbrook Technologies)

NK Labs Principal Engineer, Seth Newburg, presents a walkthrough of the X-ray inspection system with new automation features and software developed by NK Labs. Video credit Robin Zweig.